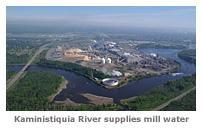

Our pulp and paper manufacturing process requires vast amounts of fresh water. This process also generates large amounts of wastewater. The water we use comes from—and returns to—the

Kaministiquia River (Kam River). To keep our mill running properly and to protect this valuable resource for our community, we make every effort possible to keep our river ecosystem healthy.

On site, the mill has installed mill controls and an advanced

effluent treatment plant to ensure our wastewater is treated beyond what government regulations require.

Off site, mill personnel participate on

watershed management teams, which evaluate the relative health of the river and assess the impact our effluent has on the environment.

There are a number of projects and field studies being worked on;

For example, the provincial government and operators of hydroelectric plants are conducting a province-wide program to better manage our watersheds. In the case of the Kam River, Ontario Power Generation (

OPG) is the operator of the dams at Dog Lake and Shebandowan Lake which feed the Kam. As a major user of the river, our mill was asked to participate in the Kam River Watershed Management Plan—by sitting on a Public Advisory Committee (PAC). The PAC includes major users of the river and allows their concerns to be considered while preparing the plan. The government uses this input when setting operating limits for

OPG.

Because of the lack of rain and lower than normal snowfall, resulting in low flows in the river, the mill is very careful about the quality of

effluent that we discharge into the river.

All rivers and lakes have a capacity to absorb and handle organic material, similar to what the mill discharges. This organic material is measured as Biochemical Oxygen Demand (

BOD). As the name suggests, the more organic material discharged, the higher the demand for oxygen needed to break it down. When there is a large quantity of organic material in the river, there is less oxygen available for fish and other aquatic organisms.

The mill has strict effluent limits set by the Federal and Provincial governments for

BOD. The Resolute mill has volunteered to conduct a study to evaluate the impact of our BOD discharge on the river during low flow conditions. A similar study has not occurred in almost 20 years.

A consultant will use Ministry of the Environment protocols to measure oxygen levels in the river, and will run a computer model to evaluate the impact of the mill on the river. This study can only be done under low flow, warm water conditions in the river.

The Resolute mill is also about to conduct another study project: an Environmental Effects Monitoring Study (

EEM). This study is required under the Federal Pulp and Paper Effluent Regulations, and is conducted every 3 years. It involves a comprehensive monitoring program “in the field” to establish the effects of the mill’s effluent on the river habitat. Monitored subjects include fish populations, fish health, and other environmental indicators. Readings taken downstream from the mill are compared to historical data and to results from upstream. These readings are then compared to a reference area, which has had no contact with mill effluent. The first study occurred in 1994. A dramatic improvement in the health of the river downstream from the mill was noted between the first study and the second study. This study will be conducted in September 2018 with further improvements expected.

In addition, the mill’s ongoing Water Effluent Reduction Program is another critical component of our strategy to reduce the impact of the mill on the Kam River.

Participation in these projects supports Resolute Forest Products goal to continually improve our environmental performance.